Parallax is the optical illusion that causes objects to appear aligned if they're not in the same plane, when viewed from a different angle. Well, that's the textbook definition, but what does that really mean? Assume you're sitting in the passenger seat of a car and your friend is driving. If you look at the speedometer, it may appear to you that he is driving at, say, 75 mph, when he's really driving at 70 mph. This is because you are viewing the speedometer from an angle and since the speedometer needle is at a different plane than the dial behind it, you think the speedometer is showing a different speed than your friend, who is sitting in the driver's seat. This optical illusion is called the parallax effect.

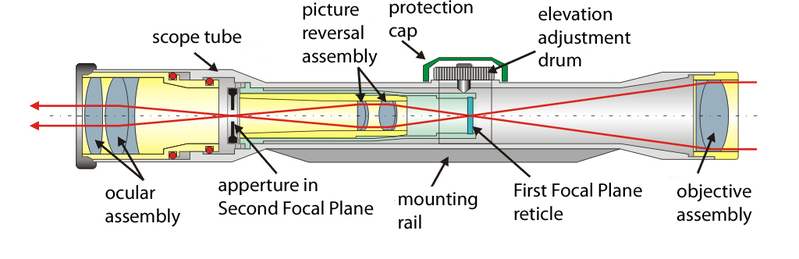

So now that we know what parallax is, how does it apply to scopes? Assume a simple scope with only two lenses, an objective lens and an ocular lens, and a reticle in between (yes, real scopes have more than two lenses, but let us imagine the simplest case for the purposes of this discussion). If the reticle is not placed at the focal plane of both lenses in the scope (i.e.) if the focal length of either of these two lenses is not exactly the same distance as the distance from the lens surface to the reticle, then parallax error happens. Due to this focusing error, moving the eye behind the eyepiece causes the reticle to appear to point to different parts of the target. Therefore, this makes aiming dependent on where the user places his head, which may cause the user to miss smaller targets, because he thinks he's aiming at the target while he's really aiming to one side of it. The focal plane moves depending on the distance to the target, so if the scope does not show any parallax error for a target at one particular distance, it will show parallax error when viewing another target at a different distance.

For scopes with 4x magnification or lower, the effect of parallax error is not that significant. For higher magnification power scopes or variable power scopes, the effects are bit more significant. The problem is that the focal plane moves as the distance to the target changes. So, there are a few ways to handle this:

- The simplest way is to adjust the scope at the factory, so that it is parallax corrected for the range that it is most expected to be used. This range is called the zero-parallax range. For most hunting scopes, this is typically somewhere between 100 and 150 yards and some military scopes are parallax corrected at 300 meter ranges. This is the approach used by most scope manufacturers. For targets at ranges outside what the scope is adjusted for, there will be some parallax error. However, in many cases (e.g. high powered hunting rifles), the error at ranges outside the zero-parallax range is acceptable, because the target on the other end is relatively large.

- The second method is to make the objective lens of the telescopic sight be adjustable, so that the focal plane can be moved to compensate for a target at a different distance. Such scopes are called AO or A/O models, with the letters AO standing for Adjustable Objective.

- The third method is the most complicated, but it involves making an internal lens in front of the reticle adjustable, to move the focal plane back and forth to compensate for parallax errors. Naturally, there has to be some gear mechanism to adjust the position of the internal lens. Typically scopes will have an extra parallax knob on one side and turning this knob operates the mechanism that moves the internal lens around.

So how does a person check if a scope is parallax corrected properly at a given range? The procedure is simple:

- First the person aims the scope at a target at a known range.

- Next, the person secures the rifle so that it cannot move.

- After that, the person views the target through the scope and moves his head around, without touching the rifle.

- If the reticle's cross-hairs appear to move to different parts of the target when the user's head is moved, the scope is not parallax compensated at that range. If the cross-hairs stay pointing to the same place on the target, this means the scope is parallax compensated correctly at that range.

In our next post, we will study mounting accessories for scopes.